At the British Engines Group, we are proud of our reputation as a family-run and family-oriented business. With many of our sites based across the North-East, we employ several generations of families from across the region.

Throughout the year we have been recognising the huge part that generations of local people have played in helping British Engines reach 100 years. As a North East employer we are extremely proud to have a number of families working in various roles across the group.

This week we caught up with Chris and Dylan Matthews, a father and son who work at group company, CMP Products. Chris has worked at CMP Products for over eight years and encouraged Dylan to apply for the British Engines apprenticeship scheme when he left school. Five years later, Dylan has worked in various businesses across the group and has landed a position at CMP Products working with his father.

What are your current job roles at the British Engines Group?

Chris: My role is Production Director. I’m in charge of all of the manufacturing in the machine shop, as well as the maintenance department.

Dylan: I’m a Mechanical Maintenance Technician, so I fix all of the machines that are broken and the machines he (Chris) demands to be fixed!

Chris: Or at least he tries to!

Can you describe your time so far working at the group?

Chris: I’ve really enjoyed my time here so far. I started at CMP in 2014 as Maintenance Manager and worked my way up. During this time, I started looking after the Continuous Improvement and Health and Safety departments, before transferring into my current role as Production Director about three and a half years ago. It’s been challenging but very rewarding.

Dylan: I finished my apprenticeship in September 2021 and joined CMP in May 2022. It’s a completely new job role but I find it really interesting and I’m enjoying it. I’m constantly learning new things and I get more time off with my new shift pattern which is a bonus!

What apprenticeship did you study, Dylan?

Dylan: It was a British Engines apprenticeship actually! I was a Mechanical Engineering Apprentice at group company, Michell Bearings and I transferred to CMP when I was qualified.

Chris, what made you suggest to Dylan that he joins the British Engines Group?

Chris: Dylan developed an interest in engineering when he was at school. I had told him about the opportunities at the British Engines Group, so he joined BEL Valves as an apprentice Assembly Fitter and later transferred to Michell Bearings. When the vacancy opened at CMP, I suggested that he applied because of his transferable skills and training.

What changes have you seen during your time working at the group?

Dylan: There’s been many changes, especially as departments and teams have grown. I’ve moved around the group, so I notice a lot of new faces. I spent two years at BEL Valves in assembly, inspection and testing and two years at Michell Bearings in the repair areas, building bearings, stripping them down and fault finding and now I’m at CMP working on the machines – so I’ve met many people along the way!

What was it like working at different businesses within the group?

Dylan: The group companies I have worked in have all been different in terms of what they do and the products they manufacture, but not so much in terms of how they do things. It’s been an easy transition moving from business to business and I’ve really enjoyed it.

What about you Chris, what changes have you seen during your time working at the group?

Chris: It’s changing all the time as there is always a big project to work on! When I compare it to eight years ago, it’s massively different to when I first started.

The range of products that we manufacture has increased and there’s been a lot of investment in new technology such as; lasers, automated storage machines, a nickel-plating plant, which I was heavily involved in, and a constant investment in equipment. We’ve also expanded and built a third factory, which houses the cleat manufacturing and research and development departments.

What do you think will happen at the British Engines Group over the next 100 years?

Chris: I think it will continue to grow and go from strength to strength! The group is very ambitious and are always trying to diversify into new markets and opportunities.

Dylan: Same as my dad really. The business is constantly evolving and growing.

What do you do together in your spare time?

Chris: We’re Sunderland fans so we go to football matches together and go to our local pub for a few drinks.

Dylan: We like going to the football together. I’m quite independent these days so I end up doing my own thing a lot.

Chris: Yeah, he’s always training for his mixed martial arts (MMA) and keeping himself busy! He used to run with me, but I was too quick for him.

Chris and Dylan at the races

What’s it like working for the same group?

Dylan: It doesn’t affect me really!

Chris: Dylan and I now have a bit more in common since he joined CMP. At home we sometimes talk about work which my wife doesn’t like!

What do you admire about each other?

Dylan: My dad is very hard working! He even gets up at half four and goes for a run before he comes into work.

Chris: I think Dylan is very motivated. If he sets his mind on something he tends to achieve it. It’s the same with his football and MMA, if it’s something he likes doing he tends to do really well. I had no worries about bringing him into the maintenance department. Although it is a different area for him, I knew his skills were transferable and if he puts the effort and dedication in, then I know he will do well.

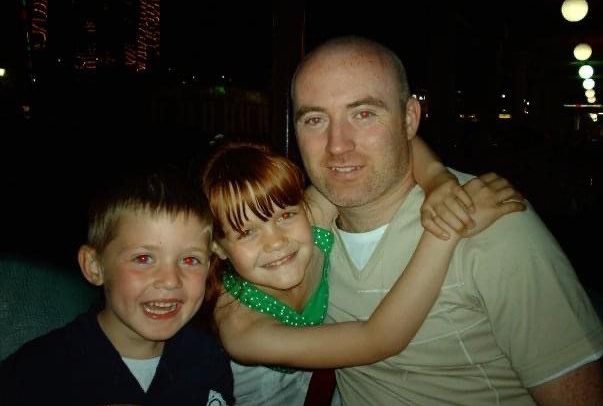

Dylan, Taylor and Chris on holiday in Gran Canaria in 2006

What’s the best piece of advice you’ve had from each other?

Dylan: When I first started my apprenticeship, I was given smaller jobs whilst shadowing other engineers. I sometimes complained to my dad when I was given small jobs because I was still at the shadowing stage. My dad told me to stick it out and reassured me that it will take time to find my feet, which came around a lot quicker than I thought!

Chris: Dylan gives great health fitness advice and tells me where I’m going wrong, especially with my diet at times. He trains hard for his MMA so it’s nice to have that support.

Find out more about the history of the British Engines Group and how we’ve been celebrating our 100 year anniversary.